Design of Welded Connections

- Concrete Cost Estimator

- Concrete Continuous Footing

- Landscape Bidding and Estimating

- Construction Cost Estimating

- Concrete and steel cost estimation

- Construction Cost Estimate Breakdown

- Construction Estimating Worksheet

- Home Construction Cost Estimate

- Estimate Pricing Sheet

- Sheet for General Contractor

- Construction Cost Estimate

- Labor Materials Cost Estimator

- Masonry Estimating Sheet

- Sheet for Building Contractor

- Construction Schedule Bar chart

- General Cost Estimator Sheet

- General Construction Estimate

- Building and Road Estimating Sheet

- Detailed expense estimates

- Door and Window Takeoff Sheet

- General Construction Cost Estimating Sheet

Structural welding belongs to a method by which the sections to be attached are heated and fused, through additional molten metal at the joint.

A comparatively small depth of material should be molten, and after cooling, the structural steel and weld metal will function as one continuous part where they are connected.

The supplementary metal is deposited from a special electrode, that is a component of the electric circuit with the connected part.

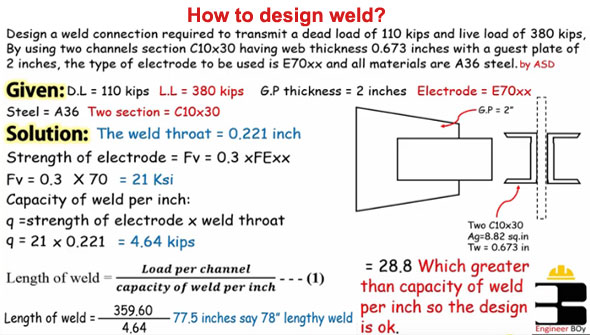

This civil engineering tutorial focuses on weld connection design.

For this purpose, solution is given on the following problem :-

Problem: Create the design of a weld connection that is provided to transfer a dead load of 110 kips and live load of 380 kips with the use of two channels section C10 x 30 containing web thickness 0.673 inches along with a guest plate of 2 inches.

The type of electrode should be applied as E70xx and all materials should be A36 steel.

The calculation is done on the basis of the following data :-

D.L = 110 kips

L.L = 380 kips

G.P Thickness = 2 inches

Electrode = E70xx

Also Read: Download estimating sheet for Welding Splice Design of Beam

Two section = C10 x 30

Gross cross section area = Ag = 8.82 sq.in

Web thickness = 0.673 inches

A36 stands for a common structural steel with least yield strength of 36 Ksi (36000 Psi)(250 MPa).

To know the complete method, go through the following video tutorial.

Video Souce: Engineer Boy

- Application of concrete calculator

- Roofing Calculator can streamline the roof estimating process

- House construction cost calculator

- Engineering column design excel spreadsheet

- Material Estimating Sheet with Excel

- Materials List and Cost Estimate Worksheet

- Concrete Slab Estimating Calculator Sheet

- Common types of foundations for buildings

- Online calculation of construction materials

- Estimating with Excel for the Small Contractor

- Concrete Beam Design Spreadsheet

- Virtual Construction Management app for construction

- Autodesk’s Project Skyscraper

- Reed Construction’s Reed Insight

- Manage your construction project documentation

- Costimator, the popular cost estimating software

- On Center Software for construction professionals

- Free Construction Estimating Software

- Plumbing Calc Pro

- Cost Estimate Worksheet

- HVAC Piping Quantity Takeoff Worksheet

- Construction Estimating Software Sheet

- Estimate Cost Templates

- Construction Punch List

- Construction cost estimating template consisting estimating basic

- Gantt Chart Template for Excel

- Download Civil Engineering Spreadsheets with Verification

- The Building Advisor Estimating and Budgeting Worksheet

- Spreadsheet for design of concrete bridge

- Construction Estimating Software Free