Variations among cement, concrete and mortar

- Concrete Cost Estimator

- Concrete Continuous Footing

- Landscape Bidding and Estimating

- Construction Cost Estimating

- Concrete and steel cost estimation

- Construction Cost Estimate Breakdown

- Construction Estimating Worksheet

- Home Construction Cost Estimate

- Estimate Pricing Sheet

- Sheet for General Contractor

- Construction Cost Estimate

- Labor Materials Cost Estimator

- Masonry Estimating Sheet

- Sheet for Building Contractor

- Construction Schedule Bar chart

- General Cost Estimator Sheet

- General Construction Estimate

- Building and Road Estimating Sheet

- Detailed expense estimates

- Door and Window Takeoff Sheet

- General Construction Cost Estimating Sheet

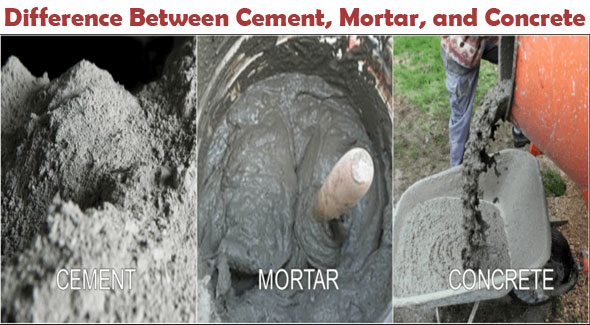

In this civil engineering article, you will come to know the basic differences among cement, concrete, and mortar.

Cement stands for a fine binding powder that is not applied individually. It is a material of both concrete and mortar along with stucco, tile grout, and thin-set adhesive.

1. Mortar is produced by combining cement, fine sands and lime. It can be applied as a binding material while making construction with brick, block, and stone.

2. Concrete stands for a very powerful structural building material that is formed with cement, sand, and larger aggregate (gravel).

Cement: Cement belongs to the binding material in both concrete and mortar. It is generally produced with limestone, clay, shells, and silica sand. These materials are compressed and mixed with other materials (including iron ore), and then heated to about 2,700 F. The material known as clinker, is grounded into a fine powder and packaged to be utilized for being mixed with several cementitious building materials, along with mortar and concrete.

Sometimes, cement is referred as Portland cement. Now-a-days, Portland cement is considered as the most common type of cement that is frequently applied in building materials. It belongs to a type of "hydraulic" cement that will set and solidify if mixed with water.

Concrete: Concrete stands for a complete building material suitable for foundation walls, concrete slabs,patios, and several other masonry structures.

Also Read: Construction tips for measuring quantity of cement and sand in Mortar

It sets forth as a simple, dry mixture, then turns out to be a flexible, semi-liquid material having ability to develop into any mold or shape, and that dries into the hard-as-rock material. In various concrete structures, metal reinforcement, like wire mesh or rebar, is included for improving the strength as well as reduce the cracking that can happen in solid concrete.

Concrete is formed with cement, sand, and gravel or other fine and coarse aggregate. The inclusion of water stimulates the cement so that it can bond the mix collectively to build a solid.

Ready-made concrete mixes can be brought into bags that amalgamate cement, sand, and gravel and only water should be added for development. These are ideal for small projects, like anchoring fence posts or building small pads. For big projects, either bags of cement should be purchased and blended with sand and gravel with a wheelbarrow or other large container. Alternatively premixed concrete can be ordered and delivered through a truck (usually known as "ready-mix" concrete).

Mortar: Mortar is another crucial building material that is formed with cement as well as blended with fine sands and water. The lime is added to enhance the stability of the product. If water is added to the mix, the cement is activated in order that it gets solidified or cured just as with concrete. Mortar does not have enough strength as concrete and normally is not applied as a solitary building material. It is the "glue" that retains bricks jointly as well as concrete block, stone, and other masonry materials.

Mortar is normally sold in bags, in a dry pre-mixed form that can be mixed with water. It can also be mixed on the construction with a cement mixer or just mixed with a shovel or hoe in a wheelbarrow or mixing tub. There exist several types of mortars which can be used for various applications. While working with brick and other masonry units, it is necessary to utilize the perfect type of mortar for the masonry, as some mortars are very stiff for some types of masonry and can lead to crack if applied inaccurately.

Grout is a product similar to mortar, but it is formed devoid of the lime additive. Mortar contains a higher water content so that it can easily flow and fill gaps among ceramic and stone tiles. Due to its high water content, grout is not treated as a binding material, but functions scarcely to fill gaps.

Thin-set is a similar product that is formed with cement and very fine sands, together with a water-retaining agent like an alkyl derivative of cellulose. It is applied to affix ceramic and stone tile to a substrate, like cement board. Some thin-sets contain latex and polymer additives to make the bonding strength superior. Thin-set contains a pronounced adhesive quality, and sometimes called as thin-set adhesive.

- Application of concrete calculator

- Roofing Calculator can streamline the roof estimating process

- House construction cost calculator

- Engineering column design excel spreadsheet

- Material Estimating Sheet with Excel

- Materials List and Cost Estimate Worksheet

- Concrete Slab Estimating Calculator Sheet

- Common types of foundations for buildings

- Online calculation of construction materials

- Estimating with Excel for the Small Contractor

- Concrete Beam Design Spreadsheet

- Virtual Construction Management app for construction

- Autodesk’s Project Skyscraper

- Reed Construction’s Reed Insight

- Manage your construction project documentation

- Costimator, the popular cost estimating software

- On Center Software for construction professionals

- Free Construction Estimating Software

- Plumbing Calc Pro

- Cost Estimate Worksheet

- HVAC Piping Quantity Takeoff Worksheet

- Construction Estimating Software Sheet

- Estimate Cost Templates

- Construction Punch List

- Construction cost estimating template consisting estimating basic

- Gantt Chart Template for Excel

- Download Civil Engineering Spreadsheets with Verification

- The Building Advisor Estimating and Budgeting Worksheet

- Spreadsheet for design of concrete bridge

- Construction Estimating Software Free