Brief overview of pile foundation

- Concrete Cost Estimator

- Concrete Continuous Footing

- Landscape Bidding and Estimating

- Construction Cost Estimating

- Concrete and steel cost estimation

- Construction Cost Estimate Breakdown

- Construction Estimating Worksheet

- Home Construction Cost Estimate

- Estimate Pricing Sheet

- Sheet for General Contractor

- Construction Cost Estimate

- Labor Materials Cost Estimator

- Masonry Estimating Sheet

- Sheet for Building Contractor

- Construction Schedule Bar chart

- General Cost Estimator Sheet

- General Construction Estimate

- Building and Road Estimating Sheet

- Detailed expense estimates

- Door and Window Takeoff Sheet

- General Construction Cost Estimating Sheet

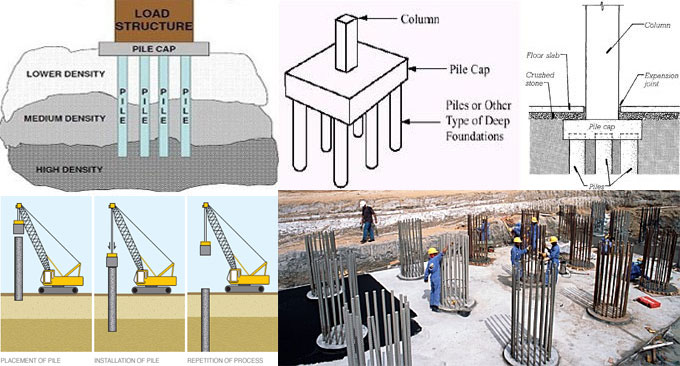

A concrete pile belongs to mainly a long cylinder in reinforced concrete covered in the ground to provide a consistent support for the structures which are required to be constructed on top of a platform supported with one or more of stated cylinders. The set is described as foundation piles or deep foundations.

Pile foundations are very effective for high buildings since the design loads are very immense which can’t be borne by spread footings. Erstwhile, when the soil contains low SBC or the soil is cloggy, a raft or a pile foundation is the best choice.

Piles are categorized as follow :-

1. The way in which the load is transmitted to the soil.

2. Method of Installation.

3. Material of construction.

Categorization of piles on the basis of load transfer

Point Bearing Piles: If bedrock or hard strata exists inside proper depth, piles are expanded to be supported on the bedrock or infiltrate necessary depth into the hard strata. Under this situation, the final bearing strength of the pile is completely based on the elementary rock/strata.

Friction Piles: In a friction pile, the load on pile is mostly obstructed with skin friction along the pile shaft. Pure friction piles are likely to be longer as compared to point bearing piles.

Resistance refers to a function of the shaft area adjacent to the soil. In cohesion-less soils, like sands of medium to low density, friction piles are frequently utilized to raise soil density. When there are no hard strata at proper depth, end bearing piles are not recommended as they can increase cost. Piles are pushed through the softer material to desired depth toward this type of subsoil condition.

Steel piles: These are mostly found in marine and other structures. Maximum length is basically infinite. They contain relatively larger load capacity.

Benefits: Larger capacity, is ideal for end bearing for various reasons like easy to splice, small displacement, capacity to penetrate through light obstructions.

Drawbacks

• Safeguard for the metal against erosion is necessary

• There is possibility for being damaged/deflected with major obstruction

Concrete Piles

• Concrete piles come in the form of precast, pre-stressed, cast in place, or composite construction.

• Precast concrete piles are formed with ordinary reinforcement or pre-stressed steel.

• Precast piles with ordinary reinforcement are developed to withstand bending stresses throughout transport as well as bending moments from lateral loads and arrange adequate resistance against vertical loads and any tension forces which may create at the time of driving.

• Pre-stressed piles are created by tensioning high strength steel pre-stressed cables. Generally, there exist higher-strength concrete (M35 to M55) in pre-stressed piles due to the large initial compressive stresses caused by pre-stressing. Pre-stressing the piles, likely to neutralize any tensile stresses throughout handling or driving.

• Max length: 10 - 15 m for precast, 20 - 30 m for pre-stressed

• Optimum length 10 - 12 m for precast. 18 - 25m pre-stressed

Benefits

1. Ability to deal with High load.

2. Corrosion resistance is possible with cathodic protection; sacrificial anodes or impressed current method.

3. Hard driving is feasible

4. Cast in place concrete piles are developed by drilling a hole in the ground & filling it with concrete. The hole is drilled or created with driving a shell or casing into the ground.

For more information, visit the following website epiengineers.com

- Application of concrete calculator

- Roofing Calculator can streamline the roof estimating process

- House construction cost calculator

- Engineering column design excel spreadsheet

- Material Estimating Sheet with Excel

- Materials List and Cost Estimate Worksheet

- Concrete Slab Estimating Calculator Sheet

- Common types of foundations for buildings

- Online calculation of construction materials

- Estimating with Excel for the Small Contractor

- Concrete Beam Design Spreadsheet

- Virtual Construction Management app for construction

- Autodesk’s Project Skyscraper

- Reed Construction’s Reed Insight

- Manage your construction project documentation

- Costimator, the popular cost estimating software

- On Center Software for construction professionals

- Free Construction Estimating Software

- Plumbing Calc Pro

- Cost Estimate Worksheet

- HVAC Piping Quantity Takeoff Worksheet

- Construction Estimating Software Sheet

- Estimate Cost Templates

- Construction Punch List

- Construction cost estimating template consisting estimating basic

- Gantt Chart Template for Excel

- Download Civil Engineering Spreadsheets with Verification

- The Building Advisor Estimating and Budgeting Worksheet

- Spreadsheet for design of concrete bridge

- Construction Estimating Software Free