How to apply perfect concrete mix design process

- Concrete Cost Estimator

- Concrete Continuous Footing

- Landscape Bidding and Estimating

- Construction Cost Estimating

- Concrete and steel cost estimation

- Construction Cost Estimate Breakdown

- Construction Estimating Worksheet

- Home Construction Cost Estimate

- Estimate Pricing Sheet

- Sheet for General Contractor

- Construction Cost Estimate

- Labor Materials Cost Estimator

- Masonry Estimating Sheet

- Sheet for Building Contractor

- Construction Schedule Bar chart

- General Cost Estimator Sheet

- General Construction Estimate

- Building and Road Estimating Sheet

- Detailed expense estimates

- Door and Window Takeoff Sheet

- General Construction Cost Estimating Sheet

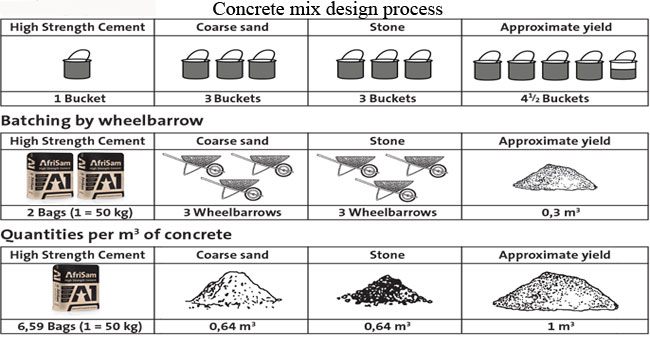

In a Concrete mix design process, the proper components of concrete and their comparative amounts are chosen so that the formed concrete contains necessary potency, workability and durability.

The functionality of the concrete mix design is based on its two characteristics like plastic and hardened state. Plastic concrete mix design is useful for compaction and arranging the concrete whereas the hardened concrete mix design provides potency to the concrete.

This feature of concrete relies on various aspects like quality and quantity of cement, quantity of water and aggregate, batching and mixing, positioning the concrete, compacting, workability and finally curing. However rich mix concrete results in condensing and rupturing on the structure. Concrete works require high investment, so its cost varies according to the cost of material, plant for production and labor.

Constraints of concrete mix design

The constraints liable for selection and portioning of mix ingredients are given below :

- The least compressive stability obligatory from structuralconsideration.

- The ample workability required for complete compaction through the accessible compacting equipment.

- Highest water-cement ratio that provides sufficient strength for the specific site conditions.

- Highest cement content to get rid of shrinkage cracking that may cause owing to temperature cycle in mass concrete.

Consequences of chemical admixture on concrete proportions: ACI 211.1-91, which was reproached in 2002, describes: “Chemical admixtures, pozzolanic, and other materials are included to concrete mix to modify some properties as well as bring required characteristics. Additives are utilized to impact the workability, reliability, compactness, potency, and endurance of the concrete.”

For more information, visit explorecivil.net

- Application of concrete calculator

- Roofing Calculator can streamline the roof estimating process

- House construction cost calculator

- Engineering column design excel spreadsheet

- Material Estimating Sheet with Excel

- Materials List and Cost Estimate Worksheet

- Concrete Slab Estimating Calculator Sheet

- Common types of foundations for buildings

- Online calculation of construction materials

- Estimating with Excel for the Small Contractor

- Concrete Beam Design Spreadsheet

- Virtual Construction Management app for construction

- Autodesk’s Project Skyscraper

- Reed Construction’s Reed Insight

- Manage your construction project documentation

- Costimator, the popular cost estimating software

- On Center Software for construction professionals

- Free Construction Estimating Software

- Plumbing Calc Pro

- Cost Estimate Worksheet

- HVAC Piping Quantity Takeoff Worksheet

- Construction Estimating Software Sheet

- Estimate Cost Templates

- Construction Punch List

- Construction cost estimating template consisting estimating basic

- Gantt Chart Template for Excel

- Download Civil Engineering Spreadsheets with Verification

- The Building Advisor Estimating and Budgeting Worksheet

- Spreadsheet for design of concrete bridge

- Construction Estimating Software Free