How to make concrete water-resistant

- Concrete Cost Estimator

- Concrete Continuous Footing

- Landscape Bidding and Estimating

- Construction Cost Estimating

- Concrete and steel cost estimation

- Construction Cost Estimate Breakdown

- Construction Estimating Worksheet

- Home Construction Cost Estimate

- Estimate Pricing Sheet

- Sheet for General Contractor

- Construction Cost Estimate

- Labor Materials Cost Estimator

- Masonry Estimating Sheet

- Sheet for Building Contractor

- Construction Schedule Bar chart

- General Cost Estimator Sheet

- General Construction Estimate

- Building and Road Estimating Sheet

- Detailed expense estimates

- Door and Window Takeoff Sheet

- General Construction Cost Estimating Sheet

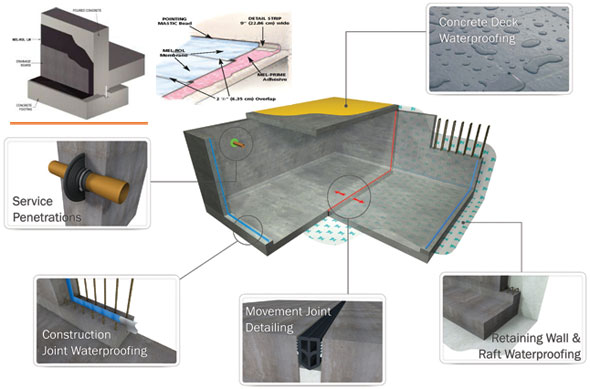

The solidity of concrete is very much required for specific construction projects ranging from water storage tanks, reservoirs, basement walls, roofs, swimming pools, sewage units, etc.

In order to make concrete water-resistant, there should not be any cracks in concrete and the proper compactness should be maintained. The compactness can be achieved with the following practices:

- Apply a superior quality Portland cement of assured quality.

- Careful enough to implement proper grading and parting of the sand, aggregate and cement.

- Use of pure and non-porous aggregate.

- Apply proper quantity of water for blending completely following exact uniformity.

- Take steps cautiously for placing, tamping and curing.

- Utilize proper water-resistant compound.

The cement concrete to some amount may be made airtight to the water through hydrophobic cement. In recent time, several flat roofs are generally formed with R.C.C. It is vital to take some actions for making the roofs water resistant.

Process for waterproofing concrete: Given below some useful processes for waterproofing of R.C.C. flat roofs:

Finishing: For conventional buildings of inexpensive construction, the completion of roof surface is accomplished while placing cement concrete. The completion of flat roof is completed in cement mortar maintaining the ratio of 1:4 i.e. one part of cement to four parts of sand by volume

Bedding concrete and flooring: With this system, the surface of R.C.C. slab is retained rough and on this surface, a layer of concrete is placed. The concrete refers to brickbats lime concrete (1:2:4) or brickbats cement concrete (1:8:14). The density of the concrete layer is around 100mm. The surface of the bedding concrete is formed with proper flooring like tiles, terrazzo, Indian patent stone, etc. A convex joint is furnished at the meeting point of parapet wall and roof.

Mastic asphalt and jute cloth: Under this system, a layer of hot mastic asphalt is placed on the roof surface. The jute cloth is dispersed on this layer. Then one more additional layer of mastic asphalt is used in order that the jute cloth is enlaced amid the two layers of mastic asphalt. The sand is then scattered over the whole surface of roof. To have superior grip, the lead sheets are placed at the meeting point of parapet wall and roof.

Uses of waterproofing compounds:Some of the waterproofing compounds like Pudlo, Impermo, etc. can be obtained from the market and If such a compound is mixed with the cement throughout construction, it blocks seepage, leakage and damp resulting from the capillary absorption of the moisture in cement, mortar and concrete. So least amount of water-proofing compound (2%) is required to be included and thus a bag of cement will need only about 10N of such compound.

The water-proof compounds can be obtained in the powder form and they should be blended completely with cement manually prior to the blending of cement with the aggregate.

Benefits of waterproofing concrete: Waterproofing concrete offers the following benefits:-

- It repairs concrete mixture proportioned wrongly.

- It restores immature green concrete.

- It produces good concrete out of the weak materials.

- It allows less rigid supervision of the workmanship.

- Application of concrete calculator

- Roofing Calculator can streamline the roof estimating process

- House construction cost calculator

- Engineering column design excel spreadsheet

- Material Estimating Sheet with Excel

- Materials List and Cost Estimate Worksheet

- Concrete Slab Estimating Calculator Sheet

- Common types of foundations for buildings

- Online calculation of construction materials

- Estimating with Excel for the Small Contractor

- Concrete Beam Design Spreadsheet

- Virtual Construction Management app for construction

- Autodesk’s Project Skyscraper

- Reed Construction’s Reed Insight

- Manage your construction project documentation

- Costimator, the popular cost estimating software

- On Center Software for construction professionals

- Free Construction Estimating Software

- Plumbing Calc Pro

- Cost Estimate Worksheet

- HVAC Piping Quantity Takeoff Worksheet

- Construction Estimating Software Sheet

- Estimate Cost Templates

- Construction Punch List

- Construction cost estimating template consisting estimating basic

- Gantt Chart Template for Excel

- Download Civil Engineering Spreadsheets with Verification

- The Building Advisor Estimating and Budgeting Worksheet

- Spreadsheet for design of concrete bridge

- Construction Estimating Software Free