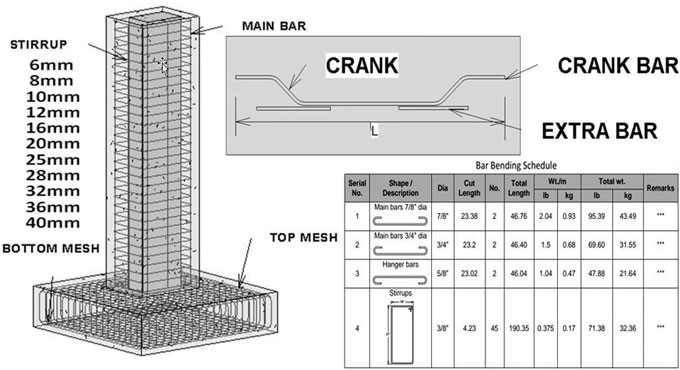

Calculation of Bar Bending Scheduling & Details

- Concrete Cost Estimator

- Concrete Continuous Footing

- Landscape Bidding and Estimating

- Construction Cost Estimating

- Concrete and steel cost estimation

- Construction Cost Estimate Breakdown

- Construction Estimating Worksheet

- Home Construction Cost Estimate

- Estimate Pricing Sheet

- Sheet for General Contractor

- Construction Cost Estimate

- Labor Materials Cost Estimator

- Masonry Estimating Sheet

- Sheet for Building Contractor

- Construction Schedule Bar chart

- General Cost Estimator Sheet

- General Construction Estimate

- Building and Road Estimating Sheet

- Detailed expense estimates

- Door and Window Takeoff Sheet

- General Construction Cost Estimating Sheet

The purpose of bar bending schedule is to convey the design intent of steel reinforcement to the fabricator and execution team to measure the weight of each size of steel.

It is an extensive list that defines the location, mark, type, size, length, number and bending details of each bar in a reinforcement drawing of a structure.

The method of listing is known as scheduling.

Bar bending schedule contains various items like member identification (beam, slab, column etc.), bar mark (top, bottom, binder etc.), shape of bending, diameter of bar, length of each bar, total numbers of bars, total length, weight.

Reinforcement bar details: The standard/maximum length available is 12 meter. It can be adjusted from 5.5 meters of length based on the usage.

Diameter and unit weight of steel: The lowest diameter of reinforcement accessible is 6 mm and the highest diameter accessible is 40 mm.

A general exists to measure the unit weight of steel is (D^2/162), where D is the diameter of steel.

Shape of bending: The shape bar that normally appears as a straight bar and available in a length of 12 meter should be cut and bent in according to the need of structural drawings.

Also Read: How to use BarBeQue software for Reinforcement Bar Bending Schedules for RCC Work

Bar mark & no’s of bars

For every structural member every bar contains a mark or a designation (top, bottom, extra, stirrups).

For members like beams, columns and walls, bars can be measured by hand from the structural drawings.

For members similar to slab, it can be computed as following :-

No. of bars = (width of concrete – 2*clear cover)/ c/c spacing among bars.

Length of each bar – It is measured from the provided structural drawings by adding the development length (if necessary), anchorage length, deduction of bends etc. Bend deduction is done on the basis of IS-2502 code.

Total weight of bars – It is measured by simply applying the formula

Wt. of a bar = (No. of bars*length*unit weight) kg.

How calculation is done

1. No of bars = (length/spacing) + 1

2. Cutting length

for 45 degrees = total length – 1(dia. of bar)(no. of bends)

for 90 degrees = total length – 2(dia. Of bar)(no. of bends)

3. For stirrups

90 degrees hook - Length of stirrups = (2A + 2B) + 20 (dia.)

135 degrees hook

Length of stirrups = (2A + 2B) + 24 (dia.)

- Application of concrete calculator

- Roofing Calculator can streamline the roof estimating process

- House construction cost calculator

- Engineering column design excel spreadsheet

- Material Estimating Sheet with Excel

- Materials List and Cost Estimate Worksheet

- Concrete Slab Estimating Calculator Sheet

- Common types of foundations for buildings

- Online calculation of construction materials

- Estimating with Excel for the Small Contractor

- Concrete Beam Design Spreadsheet

- Virtual Construction Management app for construction

- Autodesk’s Project Skyscraper

- Reed Construction’s Reed Insight

- Manage your construction project documentation

- Costimator, the popular cost estimating software

- On Center Software for construction professionals

- Free Construction Estimating Software

- Plumbing Calc Pro

- Cost Estimate Worksheet

- HVAC Piping Quantity Takeoff Worksheet

- Construction Estimating Software Sheet

- Estimate Cost Templates

- Construction Punch List

- Construction cost estimating template consisting estimating basic

- Gantt Chart Template for Excel

- Download Civil Engineering Spreadsheets with Verification

- The Building Advisor Estimating and Budgeting Worksheet

- Spreadsheet for design of concrete bridge

- Construction Estimating Software Free