Calculation of water cement ratio in concrete mix

- Concrete Cost Estimator

- Concrete Continuous Footing

- Landscape Bidding and Estimating

- Construction Cost Estimating

- Concrete and steel cost estimation

- Construction Cost Estimate Breakdown

- Construction Estimating Worksheet

- Home Construction Cost Estimate

- Estimate Pricing Sheet

- Sheet for General Contractor

- Construction Cost Estimate

- Labor Materials Cost Estimator

- Masonry Estimating Sheet

- Sheet for Building Contractor

- Construction Schedule Bar chart

- General Cost Estimator Sheet

- General Construction Estimate

- Building and Road Estimating Sheet

- Detailed expense estimates

- Door and Window Takeoff Sheet

- General Construction Cost Estimating Sheet

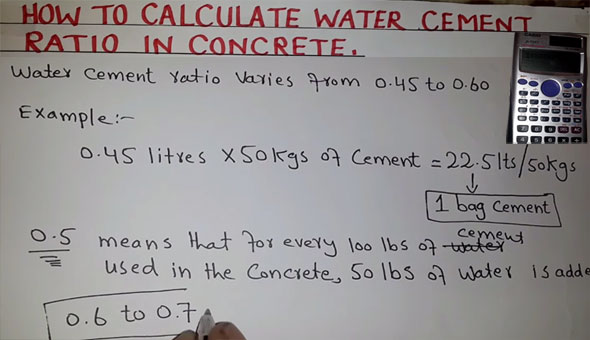

This construction video tutorial is very useful for civil engineering students to learn how to work out the ratios of water and cement in concrete work.

The water–cement ratio refers to the proportion of the weight of water to the weight of cement utilized in a concrete mix. A lesser ratio results in providing superior strength and stability, but may transform the mix problematic to deal with and build. Adaptability is maintained by applying plasticizers or super-plasticizers.

If the amount of water in a concrete mix is more, the cement paste will be more diluted. This will impact the compressive strength as well as the tensile and flexural strengths, the porosity, the shrinkage and the color.

It is recommended to apply a maximum .50 water to cement ratio as soon as concrete is uncovered to freezing and thawing in a moist condition or to deicing chemicals with adherence to the 1997 Uniform Building Code.

It is recommended to apply a maximum .45 water to cement ratio for concrete with extreme or very extreme sulfate conditions with adherence to the 1997 Uniform Building Code.

Water permeability improves significantly when there is a water cement ratio in excess of .50.

Strength gets better with lower water cement ratios. A .45 water cement ratio potentially will hit 4500 psi (pounds per square inch) or more. A .50 water cement ratio potentially will attain 4000 psi or more.

Video Source: Civil Engineers

- Application of concrete calculator

- Roofing Calculator can streamline the roof estimating process

- House construction cost calculator

- Engineering column design excel spreadsheet

- Material Estimating Sheet with Excel

- Materials List and Cost Estimate Worksheet

- Concrete Slab Estimating Calculator Sheet

- Common types of foundations for buildings

- Online calculation of construction materials

- Estimating with Excel for the Small Contractor

- Concrete Beam Design Spreadsheet

- Virtual Construction Management app for construction

- Autodesk’s Project Skyscraper

- Reed Construction’s Reed Insight

- Manage your construction project documentation

- Costimator, the popular cost estimating software

- On Center Software for construction professionals

- Free Construction Estimating Software

- Plumbing Calc Pro

- Cost Estimate Worksheet

- HVAC Piping Quantity Takeoff Worksheet

- Construction Estimating Software Sheet

- Estimate Cost Templates

- Construction Punch List

- Construction cost estimating template consisting estimating basic

- Gantt Chart Template for Excel

- Download Civil Engineering Spreadsheets with Verification

- The Building Advisor Estimating and Budgeting Worksheet

- Spreadsheet for design of concrete bridge

- Construction Estimating Software Free